The Process

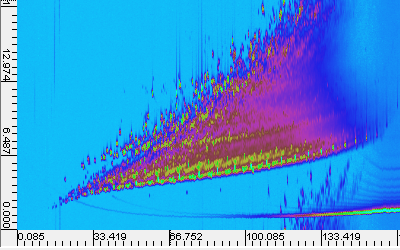

The optimization of a GCxGC system requires a

complex approach since the separation in both columns is

differently and independently influenced by column

dimensions and stationary phases, temperature

programming and carrier gas flow rates. In GCxGC, the

columns of a set are combined in series and the

possibility to apply a close-to-optimal flow regime in

both GCxGC dimensions by columns with a conventional ID

is discussed (see Posters).

The combination of

homologous diameter columns, differing in stationary

phase and film thickness, was shown to enable each

chromatographic dimension to work with a close to the

optimal flow regime resulting in an improved phase

selectivity (confirmed by system orthogonality

estimation) that partially compensated the loss of

efficiency due to wider 2D ID.

A new open tubular

capillary column called DN-UNIQUE or MEGA-2D is coated

in series with different film thickness of two different

stationary phases in a single fused silica tubing. This

column improves GCxGC performance since it avoids the

use of unions (press-fits or low dead volume

connections) between the first and the second dimension

thus eliminating a possible source of leaks and reducing

band broadening effects.

Application Notes

| AN0142 | Essential Oils, Quantitative Profiling (GCx2GC-MS/FID) |

Posters, Presentations

| P004 | Gas Chromatography and GCxGC |

| P005 | Comprehensive two-dimensional GCxGC with conventional inner diameter columns: method development and flow regime optimization |

| P006 | Comprehensive two-dimensional GCxGC with conventional inner diameter columns: new column coated with two in series different stationary phases in a single fused silica tubing |

| P007 | A new column

coated with two in series different stationary

phases in a single fused silica tubing of conventional inner diameter for Comprehensive two-dimensional GCxGC |

At

Weber Consulting we try to help our customers find the best GC products

for their application. If we do not have the solution - then we will

point you in the right direction.

At

Weber Consulting we try to help our customers find the best GC products

for their application. If we do not have the solution - then we will

point you in the right direction.